NEWS

- News Type

- Industry dynamics

- Company News

- Technical knowledge

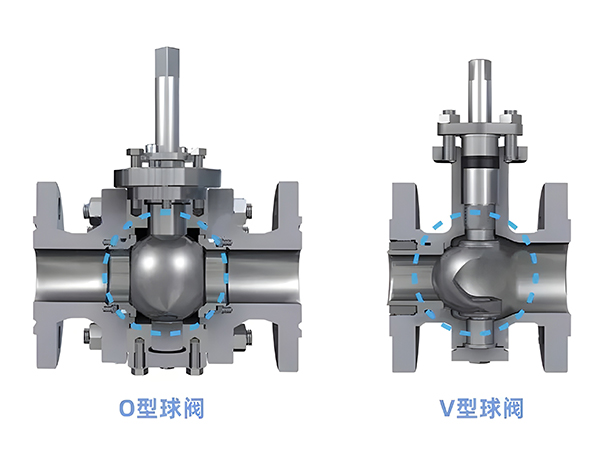

O-type ball valve and V-type ball valve difference

Ball valve has many kinds of structure, but basically the same little difference, are the opening and closing parts for the round ball core, mainly by the valve seat, ball, sealing ring, stem and other driving devices, etc., through the stem rotation 90 degrees to achieve the opening and closing of the valve, in the pipeline for shutting off, distribution, adjust the flow size and change the flow of the medium. The valve seat uses different sealing forms according to different working conditions. The valve body of the O-type ball valve is installed with a ball through the middle hole, and the ball is opened with a diameter equal to the diameter of the pipe through the hole, the ball can be rotated in the sealing seat, and there is a ring elastomer on both sides of the pipeline direction to achieve the seal. V-shaped ball valve core with V-shaped structure, the valve core is 1/4 ball shell, open V-shaped notch, large flow capacity, large adjustable range, with shear force, can close tight and other characteristics, especially suitable for fluid material with fiber conditions.

First, O-type ball valve structure:

The valve body of the O-type ball valve is installed with a ball through the middle hole, and the ball is opened with a diameter equal to the diameter of the pipe through the hole, the ball can be rotated in the sealing seat, and there is a ring elastomer on both sides of the pipeline direction to achieve the seal. By rotating the ball 90°, you can change the direction of the through hole, so as to realize the switch of the ball valve. O-type ball valve adopts floating or fixed design, and the relative moving parts are self-lubricating materials with small friction coefficient, so the operating torque is small. In addition, the long-term sealing of sealing grease makes the operation more flexible, and its product advantages are as follows:

1, O-type ball valve fluid resistance is small

Ball valve generally has two kinds of structure, diameter reduction, no matter what kind of structure, the flow resistance coefficient of ball valve is relatively small. The conventional ball valve is straight-through, also known as full-flow ball valve, the diameter of the channel is equal to the inner diameter of the pipeline, and the resistance loss is only the friction resistance of the same length of the pipeline. Of all valves, this ball valve has the lowest fluid resistance. There are two ways to reduce the resistance of the pipeline system: one is to reduce the fluid flow rate by increasing the pipe diameter and valve diameter, which will greatly increase the cost of the pipeline system. The second is to reduce the local resistance of the valve, and the ball valve is the best choice.

2, the O-type ball valve switch fast, convenient ball valve only need to turn 90 degrees to complete the full opening or full closing, so it can quickly realize the opening and closing.

3, the vast majority of ball valve seats are made of polytetrafethylene (PTFE) and other elastic materials, usually known as soft seal ball valves. The soft seal ball valve has better sealing performance, and the requirements for the roughness and processing accuracy of the valve seal surface are not very high.

4, O-type ball valve long life

Because polytetrafluoroethylene (PTFE or F4) has good self-lubrication, the friction coefficient with the ball is small. Due to the improved processing technology to reduce the roughness of the ball, thereby greatly improving the service life of the ball valve.

5. O-type ball valve has high reliability

A sealing pair of ball and seat will not cause abrasion, sharp friction and other failures;

After the valve stem is changed to built-in type, the potential accident hazard of the valve stem flying out due to the loosening of the packing cap under the action of fluid pressure is eliminated.

The ball valve with anti-static and fire-resistant structure can be used to transport oil, natural gas and gas pipelines.

O-type ball valve spool (sphere) is spherical, structurally, the ball seat is embedded in the valve body side seat when sealed. Relative moving parts are self-lubricating materials with minimal friction coefficient, so the operating torque is small, in addition to the long-term sealing of the sealing grease, making the operation more flexible. Generally used for two-position adjustment, the flow characteristic is fast opening.

When the O-type ball valve is fully opened, the two sides of the unimpeded valve form a straight pipe channel, two-way sealing, with the characteristics of "self-cleaning" performance, suitable for especially unclean and fiber containing media two-position cutting occasions. The ball core always creates friction with the valve during the opening and closing of the valve. At the same time, the seal between the valve core and the seat is achieved by the pre-tight sealing force of the valve seat against the ball core, but due to the excellent mechanical and physical properties of the soft seal valve seat, the seal is especially good.

Two, V-shaped ball valve structure:

V-shaped ball valve core with V-shaped structure, the valve core is 1/4 ball shell, open V-shaped notch, large flow capacity, large adjustable range, with shear force, can close tight and other characteristics, especially suitable for fluid material with fiber conditions. Under normal circumstances, V-type ball valves are single-seal ball valves. Not suitable for two-way use.

V-shaped edge to cut off impurities. In the process of ball rotation, the ball V-shaped knife edge is cut with the seat, thereby cutting off the fiber and solid matter in the fluid, and the general ball valve does not have this function, so it is easy to lead to the fiber impurities stuck when closed, which brings great inconvenience to repair and maintenance. The spool of the V-type ball valve is not stuck by the fiber. In addition, due to the use of flange connection form, so its disassembly is simple, no special tools, maintenance is also simple. When the valve is closed. V-notch and the seat between the chipping scissors action, and has a self-cleaning function and can prevent the ball core stuck, the valve body, valve cover and seat respectively using metal point-to-point structure, in addition to the use of a small friction coefficient of the valve stem spring, so that the operating torque is small, very stable.

V-type ball valve is a right-angle rotary structure, can achieve flow regulation, according to the V-shaped ball Angle, to achieve different degrees of proportion, V-type ball valve is generally used with valve actuators and positioners, can achieve proportional adjustment, V-type valve core is most suitable for various adjustment occasions, with rated flow coefficient, adjustable ratio, good sealing effect, zero sensitive adjustment performance, Small volume, can be installed vertically. Suitable for controlling gas, steam, liquid and other media. V-type ball valve is right-angle rotary structure, composed of V-type valve body, pneumatic actuator, positioner and other accessories; There is a natural flow characteristic of approximately equal proportions; Double bearing structure, small starting torque, excellent sensitivity and induction speed, super shear capacity.