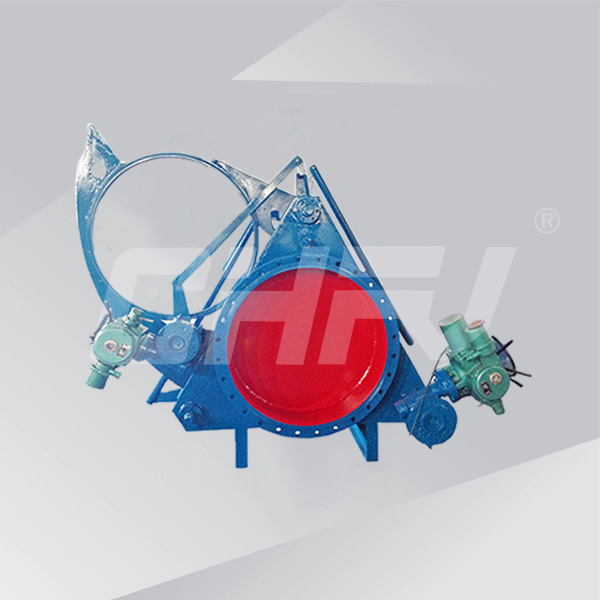

Electric blind valve

- Products

- Ball valve

- Butterfly valve

- Gate valve

- Globe Valve

- Check valve

- Anticorrosive valve

- Forged steel valve

- Regulating valve

- Hydraulic control valve

- Power station valve

- Drain valve

- Bellows valve

- Metallurgical valve

- Flame arrester and breathing valve

- Solenoid valve

- Needle valve

- Copper valve

- Ceramic valve

- Oil field valve

- Safety valve

- Actuator series

Nominal diameter: DN400 ~ 1800mm

Nominal: PN0.05 ~ 0.25MPa

Temperature: ≤450 ℃

Main material: carbon steel, stainless steel, silicone rubber

Design criteria: API 600, API6D, ASME B16.34 , 12234 GB / T

Structural length: ASME B16.10, API6D, GB / T 12221

Connection standard: ASME B16.5, ASME B16.47, GB / T 9113, JB / T 79, HG / T 20592

Pressure test: API 598, GB / T 13927 , JB / T 9092

Pressure - temperature rating: ASME B16.34, GB / T 12224

First, the product uses

This series of blind

valve according to GB6222 "Industrial Enterprise Gas Safety Regulations"

while digesting and absorbing the relevant domestic and foreign

advanced technology, based on their own research and development of a

new generation of products. Widely used in industrial and mining

enterprises, environmental protection industries such as gas, toxic gas

pipeline media, as a reliable cutting device.

Second, the structural characteristics

1, the valve by the valve body, fan valve plate, stainless steel bellows, electric drive, electric clamping devices and other components;

2, the valve body with three-point locking fan valve structure;

3, the sealing parts of stainless steel and rubber seals, reliable sealing performance, thereby increasing the service life of the seal, the seal is located on the valve plate, easy to replace the seal for maintenance.

4, electric operation, work smoothly, opening and closing flexible, reliable action;

5, clamping action using screw nut clamping, self-locking is good;

6, electric blind valve with stainless steel bellows, with flexibility, long service life and so on.

Third, the installation and use rights

1, the valve is installed, the bracket should be fixed valve base, the valve force in the action of the stent;

2, first start the electric clamp device to the left and right valve

body displacement so that the valve body and valve plate completely

separated, and then open the valve Board electric drive device is turned

on or off, and then restart the electric clip device, check whether the

left and right valve body is in close contact with the valve plate and

the electric drive device action limit switch is action;

Four, product introduction

Electric blind valve, mainly by the left valve body, right valve body,

stem, gate, seals, electric putter and other components, and by the

base, the support column to form a rigid structure. Sealing parts with

stainless steel and rubber seals, good sealing performance, long service

life, set the seal on the gate, easy to replace the seal when the seal,

rubber seals set in the gate. Electric push rod blind valve can be a

single long-distance control, remote control can also be more than one

network, under normal circumstances can also use the valve itself device

manual operation.

Five, working principle

1, the valve is opened to the valve is closed: Clamping motor action, driven screw for counterclockwise rotation, the valve body loose in place (indicator light shows), drive motor action, drive the counterclockwise rotation of the gate in place, the gate closed in place (Indicator light), clamping motor action, driven screw clockwise rotation, the valve body clamping in place (indicator shows) to complete the valve from opening to closing the whole process.

2, the valve from close to open: clamping motor action, driven screw for counterclockwise rotation, the valve body loose in place (indicator light shows), drive motor action, drive the gate for clockwise rotation, the gate opens in place, ( Indicator shows) to complete the valve from the closed to open the whole process.

Sixth, the main connection size:

| DN | D | D1 | b | n-φd | L |

| 300 | 440 | 395 | 22 | 12-φ22 | 500 |

| 350 | 490 | 445 | 22 | 12-φ22 | 500 |

| 400 | 540 | 495 | 22 | 16-φ22 | 600 |

| 450 | 595 | 550 | 24 | 16-φ22 | 600 |

| 500 | 645 | 600 | 24 | 16-φ22 | 600 |

| 600 | 755 | 705 | 24 | 20-φ26 | 600 |

| 700 | 860 | 810 | 26 | 24-φ26 | 800 |

| 800 | 975 | 920 | 26 | 24-φ30 | 800 |

| 900 | 1075 | 1020 | 28 | 24-φ30 | 800 |

| 1000 | 1175 | 1120 | 30 | 28-φ30 | 800 |

| 1100 | 1275 | 1220 | 30 | 28-φ30 | 800 |

| 1200 | 1375 | 1320 | 30 | 32-φ30 | 800 |

| 1300 | 1475 | 1420 | 32 | 32-φ30 | 800 |

| 1400 | 1575 | 1520 | 32 | 36-φ30 | 850 |

| 1500 | 1675 | 1620 | 32 | 36-φ30 | 850 |

| 1600 | 1790 | 1730 | 32 | 40-φ30 | 850 |

| 1800 | 1990 | 1930 | 32 | 44-φ30 | 1100 |

| 2000 | 2190 | 2130 | 32 | 46-φ30 | 1100 |