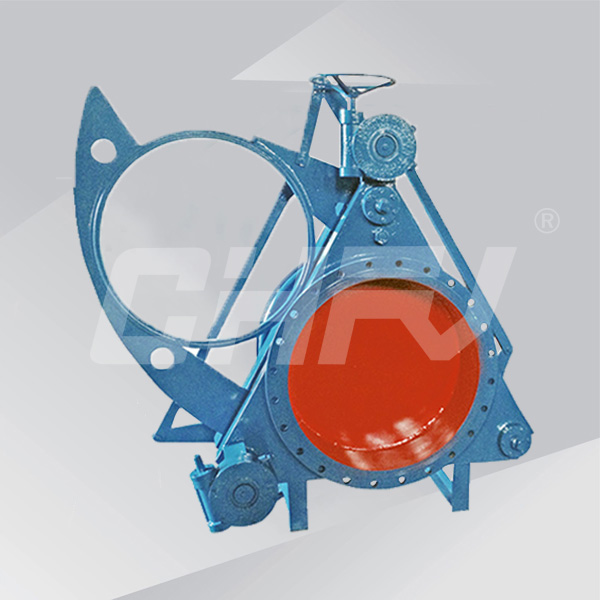

Manual worm gear blind valve

- Products

- Ball valve

- Butterfly valve

- Gate valve

- Globe Valve

- Check valve

- Anticorrosive valve

- Forged steel valve

- Regulating valve

- Hydraulic control valve

- Power station valve

- Drain valve

- Bellows valve

- Metallurgical valve

- Flame arrester and breathing valve

- Solenoid valve

- Needle valve

- Copper valve

- Ceramic valve

- Oil field valve

- Safety valve

- Actuator series

Nominal diameter: DN300 ~ 2000mm

Nominal pressure: PN0.05 ~ 0.25MPa

Suitable temperature: -20 ℃ ~ 300 ℃

Suitable temperature: 200 ℃ (silicone rubber) 300 ℃ (Viton)

Design criteria: API 600, API6D, ASME B16.34 , GB / T 12234

Structure length: ASME B16.10, API6D, GB / T 12221

Connector Standard: ASME B16.5, ASME B16.47, GB / T 9113, JB / T 79, HG / T 20592

Pressure test: API 598, GB / T 13927, JB / T 9092

Pressure - Temperature class: ASME B16.34 , GB / T 12224

First, the structural characteristics

The manual worm gear blind valve is mainly composed of the left valve body, the right valve body, the screw rod pair, the flap, the seal ring, the lever, the worm gear and other components. The rigid base body and the support column form a rigid structure body. Rubber ring embedded in the flap, with high temperature, good sealing performance, easy replacement, long service life and so on.

Second, the main performance parameters

| Nominal pressure MPa | 0.25 | 0.15 | 0.10 | 0.05 |

| Seal test pressure MPa | 0.275 | 0.165 | 0.11 | 0.055 |

| Strength test pressure MPa | 0.40 | 0.225 | 0.15 | 0.075 |

| Drive source | Compressed air 0.4-0.6MPa; Hydraulic pressure 6.3MPa; 3-phase 380V50HZ | |||

| Applicable temperature ℃ | Nitrile rubber | Silicone Rubber | fluororubber | |

| -20-100 | -20-200 | -20-300 | ||

| Suitable media | Gas and other toxic, harmful, flammable gas | |||

| Opening and closing time S | ≤60 | |||

| The main components of the material | Valve body, the gate for the carbon steel; screw for the alloy steel; nut manganese copper alloy, ductile iron; expansion device for stainless steel | |||

Third, the main connection size:

| DN | D | D1 | b | n-φd | L |

| 300 | 440 | 395 | 22 | 12-φ22 | 500 |

| 350 | 490 | 445 | 22 | 12-φ22 | 500 |

| 400 | 540 | 495 | 22 | 16-φ22 | 600 |

| 450 | 595 | 550 | 24 | 16-φ22 | 600 |

| 500 | 645 | 600 | 24 | 16-φ22 | 600 |

| 600 | 755 | 705 | 24 | 20-φ26 | 600 |

| 700 | 860 | 810 | 26 | 24-φ26 | 800 |

| 800 | 975 | 920 | 26 | 24-φ30 | 800 |

| 900 | 1075 | 1020 | 28 | 24-φ30 | 800 |

| 1000 | 1175 | 1120 | 30 | 28-φ30 | 800 |

| 1100 | 1275 | 1220 | 30 | 28-φ30 | 800 |

| 1200 | 1375 | 1320 | 30 | 32-φ30 | 800 |

| 1300 | 1475 | 1420 | 32 | 32-φ30 | 800 |

| 1400 | 1575 | 1520 | 32 | 36-φ30 | 850 |

| 1500 | 1675 | 1620 | 32 | 36-φ30 | 850 |

| 1600 | 1790 | 1730 | 32 | 40-φ30 | 850 |

| 1800 | 1990 | 1930 | 32 | 44-φ30 | 1100 |

| 2000 | 2190 | 2130 | 32 | 46-φ30 | 1100 |