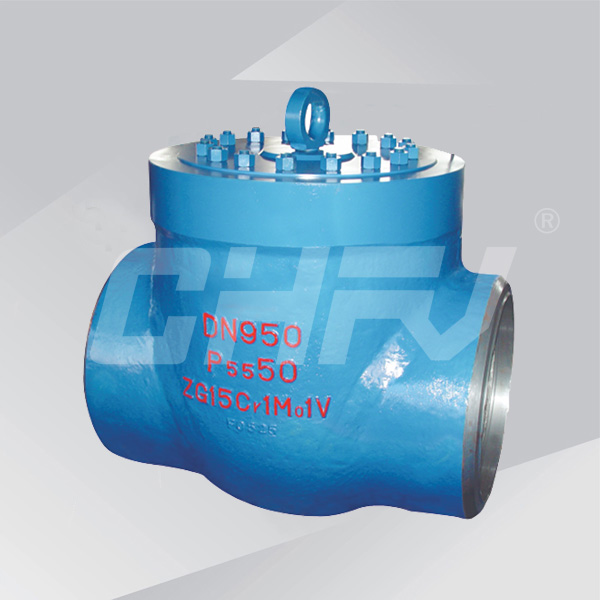

Power station pressure blocking valve

- Products

- Ball valve

- Butterfly valve

- Gate valve

- Globe Valve

- Check valve

- Anticorrosive valve

- Forged steel valve

- Regulating valve

- Hydraulic control valve

- Power station valve

- Drain valve

- Bellows valve

- Metallurgical valve

- Flame arrester and breathing valve

- Solenoid valve

- Needle valve

- Copper valve

- Ceramic valve

- Oil field valve

- Safety valve

- Actuator series

Nominal diameter: DN200 ~ 1000mm

Nominal pressure: PN1.0 ~ 32.0mpa

Temperature: 300 ~ 575 ℃

Suitable medium: water, steam

Main material: WCB, WC9, ZG15Cr1MoV

Design criteria: GB / T 12236 , API 6D, BS 1868

Structural length: GB / T 12221, ASME Bl6.10

Connection flange: JB / T79, GB / T9113, HG20594, ASME Bl6.5

Butt end: GB / T 12224, ASME Bl6.25

Test and inspection: GB / T 13927, JB / T 9092, API 598, API 6D, BS67

Blocking valve structure Description:

1, the valve is welded, straight channel without shrinking, single

plane seal, valve sealing surface heap austenitic stainless steel, block

plate with O-shaped rubber seal.

2, the use of self-tight cavity pressure seal structure, hydraulic

test or operation, can be sealed by the medium pressure to achieve a

reliable seal, and the higher the pressure, the more reliable the seal.

3, the valve body is made of high quality cast steel, both ends

processed into U-groove and pipe directly butt welding, chemical

composition and properties of the two materials are similar, excellent

welding performance, without intermediate welding transition section;

four open-loop 38CrMoAlA corrosion Nitriding, to ensure that its

heat-resistant, and wear-resistant, corrosion-resistant,

scratch-resistant, easy disassembly; cavity self-sealing gaskets, high

temperature steam corrugated asbestos gaskets, 18-8 wire braided

internal enhancements to ensure that the seal, Extend the service life;

sealing surface surfacing 1Cr18Ni9Ti, rust, erosion, repeated tests can

still guarantee the seal.

Main dimensions:

|

PN |

DN |

Size (mm) |

Weight (kg) |

PN |

DN |

Size (mm) |

Weight (kg) |

PN |

DN |

Size (mm) |

Weight (kg) |

|||

|

L |

H |

L |

H |

L |

H |

|||||||||

|

1.6 |

50 |

230 |

165 |

23 |

4 |

50 |

230 |

180 |

27 |

10 |

50 |

300 |

195 |

43 |

|

65 |

290 |

180 |

28 |

65 |

290 |

1 g5 |

33 |

65 |

340 |

213 |

52 |

|||

|

80 |

310 |

190 |

35 |

|||||||||||

|

80 |

310 |

195 |

37 |

80 |

380 |

240 |

75 |

|||||||

|

100 |

350 |

208 |

40 |

|||||||||||

|

100 |

350 |

220 |

56 |

100 |

430 |

270 |

112 |

|||||||

|

150 |

480 |

270 |

81 |

|||||||||||

|

150 |

480 |

273 |

105 |

150 |

550 |

365 |

220 |

|||||||

|

200 |

600 |

295 |

96 |

|||||||||||

|

200 |

600 |

352 |

140 |

200 |

650 |

425 |

345 |

|||||||

|

250 |

730 |

337 |

175 |

|||||||||||

|

250 |

730 |

413 |

200 |

250 |

775 |

486 |

475 |

|||||||

|

300 |

850 |

386 |

265 |

300 |

850 |

432 |

392 |

|||||||

|

16 |

50 |

300 |

255 |

52 |

||||||||||

|

350 |

980 |

430 |

364 |

350 |

980 |

455 |

396 |

|||||||

|

65 |

340 |

285 |

62 |

|||||||||||

|

400 |

1100 |

475 |

495 |

400 |

1100 |

562 |

502 |

|||||||

|

80 |

380 |

324 |

113 |

|||||||||||

|

500 |

1250 |

565 |

590 |

500 |

1250 |

620 |

645 |

|||||||

|

100 |

430 |

359 |

165 |

|||||||||||

|

2.5 |

50 |

230 |

180 |

25 |

6.4 |

50 |

300 |

1 g5 |

32 |

|||||

|

150 |

550 |

433 |

270 |

|||||||||||

|

65 |

290 |

195 |

32 |

65 |

340 |

213 |

45 |

|||||||

|

200 |

650 |

478 |

324 |

|||||||||||

|

80 |

310 |

195 |

35 |

80 |

380 |

213 |

50 |

|||||||

|

250 |

775 |

520 |

375 |

|||||||||||

|

100 |

350 |

220 |

55 |

100 |

430 |

240 |

75 |

|||||||

|

25 |

50 |

368 |

315 |

65 |

||||||||||

|

150 |

480 |

273 |

104 |

150 |

550 |

302 |

158 |

|||||||

|

200 |

600 |

352 |

138 |

|||||||||||

|

200 |

650 |

362 |

220 |

65 |

419 |

348 |

79 |

|||||||

|

250 |

730 |

413 |

198 |

|||||||||||

|

250 |

775 |

410 |

346 |

80 |

470 |

386 |

95 |

|||||||

|

300 |

850 |

432 |

388 |

300 |

900 |

468 |

476 |

100 |

546 |

410 |

172 |

|||

|

350 |

980 |

455 |

390 |

|||||||||||

|

350 |

1025 |

520 |

630 |

150 |

705 |

565 |

275 |

|||||||

|

400 |

1100 |

562 |

498 |

400 |

1150 |

572 |

886 |

200 |

832 |

320 |

325 |

|||

|

500 |

1250 |

620 |

643 |

500 |

1400 |

625 |

1030 |

250 |

991 |

676 |

395 |

|||