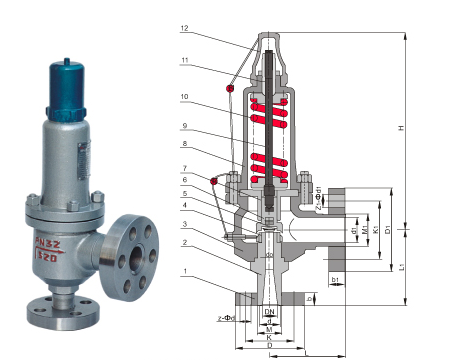

Spring Kaiqi closed high-pressure safety valve

- Products

- Ball valve

- Butterfly valve

- Gate valve

- Globe Valve

- Check valve

- Anticorrosive valve

- Forged steel valve

- Regulating valve

- Hydraulic control valve

- Power station valve

- Drain valve

- Bellows valve

- Metallurgical valve

- Flame arrester and breathing valve

- Solenoid valve

- Needle valve

- Copper valve

- Ceramic valve

- Oil field valve

- Safety valve

- Actuator series

Nominal diameter: DN20 ~ 400mm

Nominal: PN1.6 ~ 10.0MPa

Operating temperature: ≤300 ℃

Body material: steel, forged steel, stainless steel

air, LPG and liquid: Medium

Applications : Suitable for chemical, petrochemical, petroleum, papermaking, mining, electricity, Liquefied petroleum gas, food, pharmaceutical, water supply and drainage, municipal, mechanical equipment, electronics, urban construction and other fields

Product Overview:

A42Y spring fully enclosed closed high-pressure safety valve for a variety of light and heavy industry and building pipelines. Safety valves are widely used in: chemical, petrochemical, petroleum, paper, mining, electricity, liquefied petroleum gas, food, pharmaceuticals, water supply and drainage, municipal services, machinery and equipment support, electronics industry, urban construction and other fields. A42Y spring fully enclosed closed high-pressure safety valve for operating temperature ≤ 300 ℃ air, petroleum gas, liquid and other media equipment and piping. A42Y-P-type and A42Y-R-type for operating temperature ≤ 200 ℃ corrosive media equipment and piping, as over-voltage protection device.

| product name | A42Y spring fully enclosed closed high-pressure safety valve |

| Product number | A42Y |

| Nominal diameter | DN20-400 |

| Pressure range | 1.6MPa-10.0MPa |

| Body material | Cast steel, forged steel, stainless steel |

The main parts and materials:

| NO. | Part Name | A42Y-C / KA42Y-C material | A42Y-P / KA42Y-P material | A42Y-R material | DA42Y-P material |

| 1 | Seat | 2Cr13 / 1Cr18Ni9Ti | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | ZG1Cr18Ni9Ti |

| 2 | Body | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | LCB / ZG1Cr18Ni9Ti |

| 3 | Adjustment ring | 2Cr13 / 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 4 | Backlash plate | 2Cr13 / 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 5 | Disc | 2Cr13 / 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 6 | Guide sleeve | 2Cr13 / 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 7 | cap | ZG230-450 | ZG230-450 | ZG230-450 | ZG1Cr18Ni9Ti |

| 8 | spring | 50CrVA | 50CrVA coated fluoroplastic | 50CrVA coated fluoroplastic | 50CrVA |

| 9 | Valve stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 10 | Adjust the screw | 45 | 2Cr13 | 2Cr13 | 2Cr13 |

| 11 | Bonnet | ZG200-400 | ZG200-400 | ZG200-400 | ZG230-450 |

| 12 | Sealing surface material | Surfacing Co-based cemented carbide | |||